Finding and keeping skilled talent is one of the auto industry’s largest challenges, especially in service and reconditioning. Your best bet is developing, training and relying on your own talent first. Therefore, getting the right information into the hands of the end user at the right time is vital. This data then becomes actionable when a technician is given reliable information with which to do his or her work — they will understand their role and why it is important to the whole process. The employee makes better decisions knowing their work matters and is automatically transparent to all. All of a sudden, accountability has legs. Workers become self-motivated knowing their effort is visible.

Workflow in reconditioning brings this same level of accountability by connecting your recon steps together by using real-time with mobile and text notifications. The average time to market (TTM) determines the number of inventory turns your used car business is producing, and a higher number of turns, of course, creates more sales and added profit opportunity. The average time to market is the sum of all times for the work completed at each step, and each step has a responsible individual(s) and manager. Workflow also displays the average time to market for each step and every car.

A dealership’s time to market includes every hour of every day, until a car is on the frontline and available for sale. Winning in the used car business means that you are getting your cars through recon consistently faster than your competition, and that takes individual accountability, which is visible as part of the team score, or TTM.

For decades, some dealers have manually tried to keep an up-to-date tally/scorecard for their workers by using a spreadsheet. This rudimentary practice may have gotten them by for many years, but it can no longer do so. It is impossible to keep up-to-date spreadsheets when entering data by hand. Spreadsheets provide no visible transparency or accountability; therefore, workers become less motivated and less accountable to complete their work in an efficient manner. A workflow system that has management oversight, and where individuals feel properly recognized for their work, overcomes all the deficiencies of a spreadsheet.

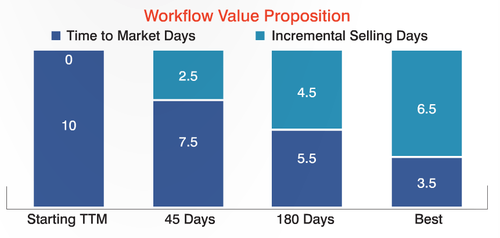

The implementation of a workflow system is straightforward. First, existing processes are captured in a template that identifies who is responsible for each step and all notifications required for accountability. Second, the DMS inventory data is connected to the workflow so the entire used car inventory is synchronized at least daily. Third, the training of users is accomplished using Web conference technology. Finally, after 45 to 60 days, a time-to-market baseline becomes visible somewhere in the seven-to-10 day range. From this point forward, a target is set and the scoreboard is used to maintain a three to-five-day average.

Another advantage of workflow performance metrics is that it scales with volume, process and user changes. It also works with external vendors, who can be held accountable for their work in areas such as glass, paint and body, wheels, and even photos and outside detail.

For every day the time-to-market factor is reduced, another selling day is added. For every 2.5 days of reduction — based on 100 cars per month — another complete inventory turn is created.

Dennis McGinn is the founder and CEO of Rapid Recon. He can be contacted at 866.268.3582, or by e-mail at dmcginn@autosuccessonline.com.